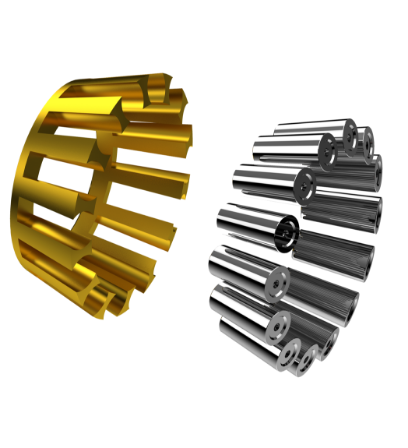

The use of tapered roller bearings is at the heart of our products and defines GEPY Swiss Precision.

This technology, developed and perfected in our Geneva premises, is the result of our global reputation for high precision and reliability. Tapered roller bearings are at the core of our products, offering several significant advantages:

- Optimal precision : They ensure unmatched concentricity and rotational accuracy, which are essential in demanding industries such as watchmaking, aeronautics, medical and precision mechanics.

- Durability and resistance : Their robust design guarantees superior resistance to radial and axial loads, thus extending the lifespan of our products.

- Rigidity : Our bearings provide consistent performance, essential for precise and efficient operations, even under high loads. The design of these bearings allows for constant play compensation, resulting in absolute precision.

- Spherical balls between circular raceways

- Primarily radial loads, limited axial capacity

- Lesser precision under heavy loads

- Less resistant to heavy loads

- Lower shock resistance

- Can generate more noise and vibrations under certain loads

- Tapered rollers between conical raceways

- Constant play compensation

- High precision under heavy loads

- Significantly larger contact surfaces allow a very little space with similar load resistance

- Combined load handling (radial and axial) due to the conical shape

- High precision under heavy loads

- Better shock resistance due to robustness

- Significant reduction in vibration

check_circle

check_circle